(video: KUKA)

Resistant to ice and cold

Whether in soup, for a salad or on meat: frozen herbs are popular kitchen helpers. To prevent them from sticking together, turning black or changing their flavor, the cold chain must be perfectly maintained. This also applies to packaging and transport. The French market leader DARÉGAL knows this – and is therefore now relying on Arctic automation. In order to supply all its customers with herbs ranging from basil to garlic to mint, two KR QUANTEC PA Arctic units started work at the site in Milly-la-Forêt, south of Paris, at the beginning of 2021.

Without a protective suit, the KUKA robots operate at temperatures well below zero degrees Celsius, and their resistance to cold makes them ideal for the food industry. At DARÉGAL, they palletize small packages of frozen herbs at minus degrees 25Celsius, which are then delivered to restaurants and retailers. It’s a task that previously had to be done manually by one employee on each packaging line, which operates in three shifts, five days a week.

“We opted for automation to stop subjecting our employees to these difficult working conditions,” says Bruno Jarrosson, industrial director at DARÉGAL. A crucial factor here: maintaining the cold chain. The KR QUANTEC PA Arctic from KUKA was therefore chosen for the automated palletizing line, because it is the only robot on the market worldwide that can be used in deep-freeze applications without a protective cover.

The KR QUANTEC PA Arctic is suitable for environments down to minus 30 degrees Celsius

The KR QUANTEC PA Arctic was created precisely for environments like those at DARÉ-GAL. The cold-resistant adaptation of the proven standard palletizer in the KR QUANTEC series also impresses with a reach of more than three meters, short cycle times, and high stacking precision. It is available for payloads of 120, 180 and 240 kilograms. “Since the robot does not require a special protective suit for cold environments down to minus 30 degrees, the user saves costs,” says Tanguy Lyvinec, business development manager at KUKA. He adds, “The robot arm also doesn’t need to be specially heated to work in the cold.” As far as outside temperatures are concerned, the KR QUANTEC PA Arctic is flexible: not only can it be used in sub-zero temperatures, but the robot also operates abso-lutely reliably at up to 10 degrees plus.

Challenges mastered ice cold

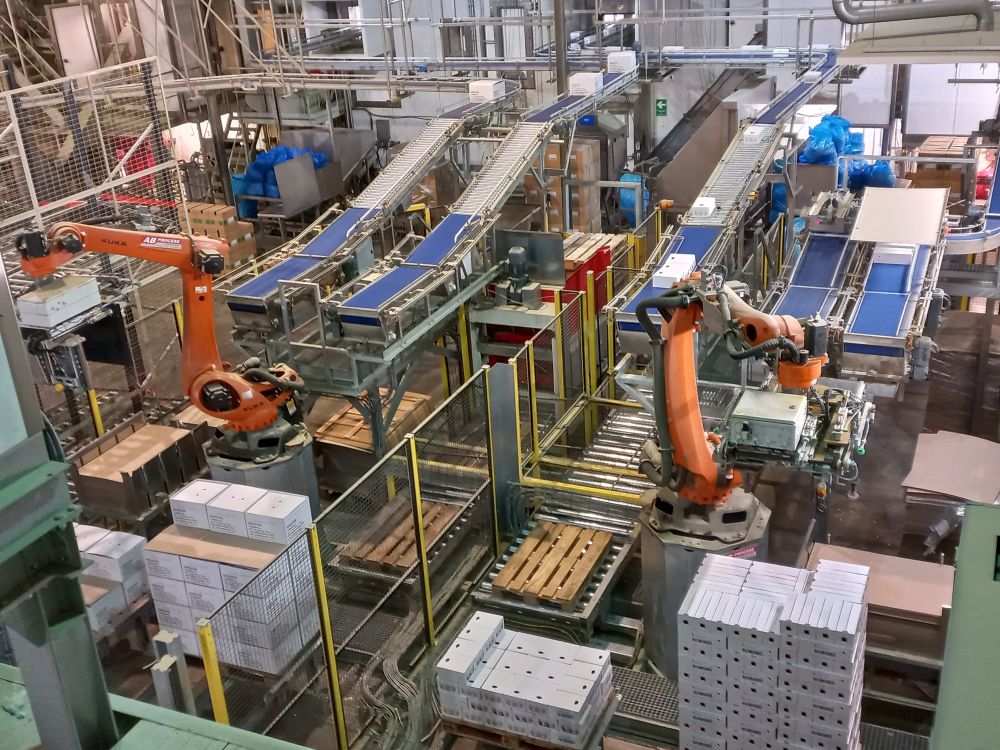

The system was installed by KUKA Integrator AB Process Ingénierie. Various challenges had to be overcome: In an area of no more than 80 square meters, the two robots had to be installed in such a way that the safety of the employees, who continue to work in the vicinity of the robots, could be guaranteed. No jobs were lost as a result of using the robots at the world market leader: the employees who were previously responsible for manual palletizing have been trained and now look after the operation of the system.

Another challenge during installation: to arm the complete system with all components against the enormous cold conditions in the deep-freeze warehouse. “At such low temperatures, plastics quickly become stiff and can break. A rolled cable, for example, can withstand the cold under static conditions, but not in motion,” explains Brian Boulanger, CEO of AB Process Ingénierie.

Flexible operation thanks to suitable software

After several tests in a specially prepared warehouse and detailed adjustments on site at DARÉGAL, the system was ready to go into operation. It is combined with the palletizing software KUKA. FlexPal. This enables extremely fast commissioning of complete palletizing applications without extensive programming knowledge. “The individual scenarios can be flexibly adapted on the user interface of the KUKA smartPAD,” says Tanguy Lyvinec from KUKA. This allows DARÉGAL employees to start 35 different palletizing plans with just a few commands.

The two KUKA robots organize and synchronize themselves to palletize the various packaged products simultaneously. They enable the French world market leader in frozen aromatic herbs to improve the working conditions of its employees, increase the quality of the pallets produced and at the same time ensure compliance with the cold chain. As a next step, DARÉGAL is planning robot-assisted palletizing of unpackaged industrial products.