Three different process configurations

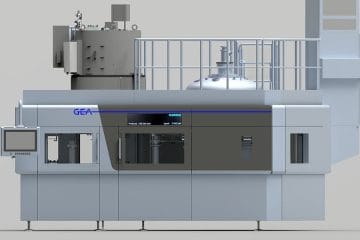

The CDC Flex is designed to operate in three different process configurations — continuously at low or high throughput, or in batch mode with immediate direct compression of pre-blended product — at output rates of 1–200 kg/h. It can also handle R&D batches as small as 1.5 kg. This is enabled by the ability to swiftly switch between different-sized continuous blenders within a single unit.

“This brand-new addition to the ConsiGma® portfolio has been designed as a truly versatile system that offers both high and low throughput functionality,” said Dr Jim Holman, Senior Director Technology Management, GEA Pharma Solids. “This agility makes the CDC Flex ideal for both R&D projects and commercial-scale production runs. In addition, for companies with a wide product portfolio that wish to benefit from the advantages that CDC offers, we now have a solution: ultimate flexibility in continuous direct compression.”

“We believe that continuous tableting delivers significant value to our customers, primarily by accelerating time-to-market through a compressed development phase and by enhancing supply chain flexibility. It also helps to reduce development costs while improving product quality and sustainability,” said Filipe Gaspar, Vice President of Technology Intensification at Hovione. “Through our collaboration with GEA, we aim to advance the continuous production of oral solid dosage forms, making the technology more standardized, accessible and cost-efficient for pharmaceutical customers.”