by N. S.

One platform, three levels of flow pack performance

Where does the rethink of the Flow Pack portfolio begin? Lattarulo explains that it originated “from a precise market demand: scalable solutions open to sustainable materials. For this reason, the range is structured around three models:

- FP-ONE – a compact, accessible and reliable entry-level unit that serves as the gateway solution in ACMA’s Flow Pack portfolio;

- FP-PRO – a hot-seal and cold-seal machine running up to 150 m/min and accommodating multiple bag styles (pillow, slug), representing ACMA’s best-selling solution;

- FP-EDGE – the top-of-the-range cold-seal model, featuring 150 m/min unwinding speed and up to 1,000 packs per minute; our answer to the most sophisticated productions, thanks to integrated digital technologies and the ability to handle both standard substrates and next-generation, paper-based materials.”

Each model preserves the same ergonomics, maintainability and capacity for digital upgrades, simplifying operator training and spare-parts management.

ACMA’s FP-ONE/PRO/EDGE series provides a horizontal platform able to:

- handle both conventional films and paper-based substrates thanks to hybrid technology; (FP EDGE only)

- reduce waste with different technologies, for example vision systems;

- enable remote service, helping customers keep maintenance costs under control;

- adapt to different markets without sacrificing time-to-market.

“Putting the customer at the centre of a convergent material–machine–converter supply chain,” Roberto Lattarulo explains, “means guaranteeing today the flexibility that will be needed tomorrow.” ACMA turns this commitment into concrete technology: a system that can run at up to 1,000 packs per minute yet has the agility to stop at exactly the right moment, avoiding the loss of even a centimetre of film”.

Hybrid films today, pure paper tomorrow: the supply chain conversation

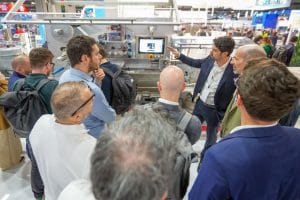

At the centre of the Milan demo was the FP-EDGE running an 80/20 film: “eighty percent paper, twenty percent barrier layers of different materials,” Lattarulo explains. “That is exactly what customers are asking for: invest today in machinery that will last for decades, ready for traditional substrates, for next-generation materials… and for whatever comes after.”

Flexibility is ensured by an “open” architecture: “Our engineering team can tune the machine to any film. Saying ‘paper-based’ is not enough—every paper behaves differently, and its response can even change when printed with different inks.”

The marketing manager images the customer at the centre of a perfect triangle, where material, machine and converting must be communicated. “If the film producer doesn’t talk to the converter, and the converter doesn’t talk to us as machine builders, the result can be operational disaster. We work side by side with everyone, and the successes we’ve achieved with leading customers prove it”.

The pneumatic buffer: the hearth ot the film handling

Switching to less-elastic substrates requires delicate treatment—hence ACMA’s patented pneumatic buffer. “We’re talking about a vacuum dynamic buffer that keeps web tension exactly right,” the manager explains. If the line “loses” a product, no pouch is formed: the loop absorbs the surplus film and feeds it to the next piece. Performing this at one thousand bars per minute may sound like science fiction, yet FP-EDGE does it continuously, cutting waste, preserving wrapper integrity and protecting its appearance.

Vision systems and predictive diagnostics

It’s not just mechanics—the FP series is digital. Ultra-high-definition cameras let operators detect defects that are invisible to the naked eye at production speed. “We’re also rolling out automatic alert functions to prevent errors,” the manager adds.

The ACMA Connect service enables remote connectivity: “From our control room in Bologna we can access machines installed anywhere in the world, cutting downtime and—not a minor detail—CO₂ emissions, because we avoid unnecessary travel.”

Time-to-Market: from development to lead time

ACMA distinguishes two timelines:

- Product time-to-market — from concept to launch. “Marketing, R&D, sales and operations share common goals, so a new product can reach the market in a little over a year. You don’t always need disruptive innovation; sometimes incremental improvement is enough, but it must be tangible.”

- Order lead time — from order intake to delivery. “We have introduced automotive-style in-cell logic for machine groups with similar cycles, allowing us to ship faster when speed makes the difference.”

Cutting waste, energy use and footprint while boosting productivity

Sustainability also comes from efficiency and footprint. “Our technical support team evaluates the entire life cycle: less material, less scrap, lower energy consumption.” The pneumatic buffer is one example; another is the CW 1400 for chocolates, which, with the same footprint as the previous CW 1005, delivers 40% more output: “Customers want productivity per square metre, and we give it to them. On these points there can be no compromise. We have just launched the CW 1400, our high-end chocolate machine. Producing 1,400 chocolates per minute within the same footprint where you used to make 1,000 is a major step forward for the customer.”