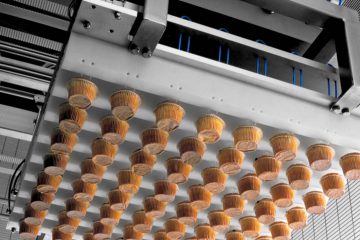

The sample of a vertical injection line to fill the panettone.

(video: Alimec)

Food filling system can be done in baking pans or on a topping conveyor directly. Depending on the needs of the customer, vertical or horizontal injection is available, with single or double colors.

The food filling system system vertical and horizontal

Over recent years, Alimec has excelled in innovation and developing new filling systems, such as the vertical and horizontal injection using a single head, double-colour fillings and introducing the absolutely revolutionary co-injection system, which injects two fillings, one into the other.

Alimec realize several filling system lines:

- the line for vertical filling of products on conveyor belt;

- the line for vertical filling of products in pans;

- the horizontal injection line.

The line for vertical filling of products on conveyor belt

A line suitable for vertical injection of poured or leavened products directly on a conveyor belt. Volumetric injection unit driven by servomotors for a wide range of fillings and high accuracy. Maximum precision in the handling and placement of products during the injection phase. PLC and display (HMI) for production line control, data and recipe storing. This food filling system line can be manufactured according to customer requirements and with the following options for different product configurations in the same line:

- individual product detecting device: no product, no injection;

Filled baked goods. (photo: Alimec) - heated hopper with adjustable temperature;

- additional injection head for rapid change of filling flavour;

- codified sensor for injection plate recognition according to the selected recipe;

- rapid release system of injection plate for a quick product type change;

- possible double-colour injection;

- extractable head on a side trolley for cleaning operations;

- automatic feeding system of fillings into the hopper.

The line for vertical filling of products in tray

A line for injecting poured or leavened goods vertically into moulded baking pans. For a wide variety of fills and great precision, use a volumetric injection head operated by servomotors. Pan management system constructed of materials that reduce noise and pan wear and tear. During the injection step, the handling and positioning of pans must be done with extreme precision. For production line control, data and recipe storage, a PLC and display (HMI) is used. This production line can be customized to meet the needs of the customer, with the following options for pan size and product configuration:

- heated hopper with adjustable temperature;

- additional injection head for rapid change of filling flavour;

- codified sensor for injection plate recognition according to the selected recipe;

- rapid release system of injection plate for a quick product-type change;

- possibility for double-colour injection;

- automatic feeding system of fillings into the hopper.

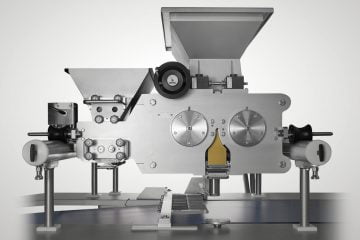

The horizontal injection line

A line suitable for the injection of poured or leavened products directly onto a conveyor belt. Volumetric injection unit driven by servomotors for a wide range of fillings and high accuracy. Maximum handling and placement precision of products during the injection phase. PLC and display (HMI) for production line control, data and recipestorage. This production line can be manufactured according to customer requirements and with the following options for different product configurations in the same line:

- individual product detecting device: no product – no injection;

- heated hopper with adjustable temperature;

- additional injection head for rapid change of filling flavour;

- codified sensor for injection plate recognition according to the selected recipe;

- injection plate rapid release system for a quick product type change;

- possibility for double-colour injection;

- extractable head on a side trolley for cleaning operations;

- automatic feeding system of fillings into the hopper.